Selected Publications

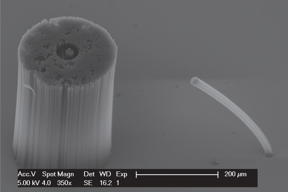

The objective of this study was to test the mechanical durability of a polyurethane/organoclay nanocomposite modified with perfluoroalkyl methacrylic copolymer in conditions that replicate extended rain impact. Samples were impacted with 1.4 mm droplets at a velocity of 24 m/s and a flow rate of 0.78 gpm for a period of 5 hours by an axial full cone nozzle. The cases of the spray nozzle being placed vertically above a sample as well as at a 40° angle were examined. After the spray period, samples were heated at 100° C to allow saturated liquid to evaporate from the surface. Contact angle and sliding of the superhydrophobic surfaces were measured before and after the spray period. A decrease in performance for both samples was observed, with the vertically sprayed sample seeing greater degradation. SEM images of superhydrophobic samples before and after spray impact revealed large amounts of circular indentations on the surfaces caused by the impacting droplets which, along with leaching of the fluoroacrylic copolymer, was likely the cause of the decrease in performance.